Keep Your Shipments Moving — Anywhere in the World — ISPM-15

Certified Compliance for Every Shipment

ISPM-15 Certified Facility

Trusted by logistics providers and exporters. We provide certified ISPM-15 Heat and Fumigation services to ensure all pallets and crates meet international export regulations.

Complete Traceability

Each treatment includes a digital certificate with traceable details for easy verification and audit compliance. Our transparent documentation keeps every shipment fully compliant across all borders.

Bulk Processing

Optimized for pallet fleets and high-volume exports. Our high-capacity chambers ensure consistent treatment results and fast turnaround for manufacturers and logistics partners.

Our treatment facilities are fully accredited under the International Plant Protection Convention (IPPC) standards for ISPM-15 compliance, offering both Heat and Fumigation treatment. Every treated pallet, crate, or dunnage piece is tracked, verified, and stamped with a unique treatment code traceable to our facility.

We maintain strict adherence to phytosanitary standards recognized by major trade regions, including the EU, USA, Australia, China, and ASEAN nations, ensuring your shipments meet customs clearance without costly delays or rejections.

Key benefits:

- Globally recognized certification and traceable treatment codes

- Updated compliance protocols under IPPC and NEA guidelines

- Seamless cross-border clearance for export logistics partners

Digital Records for Full Compliance Confidence

We understand that exporters and procurement teams need both compliance and audit-ready documentation. Each treated batch includes:

- A digital treatment certificate with ISPM-15 details (facility code, date, and method)

- Photo records and temperature logs where required

- Option for integrated compliance tracking in your shipment management system

This transparent system ensures that every shipment through Yat Guan can be verified, tracked and complied with, facilitating post-shipment audits and trade verification for your peace of mind. With secure electronic record keeping, support for regulatory audits and a global logistics network, you can be confident that compliance remains seamless from shipment to final destination.

Industrial Capacity for High-Volume Operations

We designed our facilities for large-scale, high-throughput operations to serve manufacturers, freight forwarders, and logistics providers. Our computer-controlled heat chambers and sealed fumigation units process bulk shipments and pallet batches, delivering consistent results across large volumes with short turnaround times.

- High-capacity chambers for industrial-scale treatment

- Efficient batch processing to reduce logistics bottlenecks

- Cost-optimized solutions for recurring export volumes.

- Preparation & Sorting: Your pallets, crates, dunnage, or other wood packaging materials are inspected and prepared for treatment. Only solid wood requires treatment; materials like plywood an LVL are exempt from ISPM-15 requirements.

- Loading Heat Chamber: The wood is then loaded into our specialised heat chambers designed to control temperature and airflow for uniform heating.

- Heating: In the chamber, wood is heated to a core temperature of at least 56°C (132°F) for a continuous 30 minutes, with sensors monitoring to ensure the required level is reached and maintained.

- Verification & Monitoring: Throughout the process, temperature data is recorded to verify compliance with ISPM-15 standards. If the wood does not reach the required temperature, the process may be extended until compliance is confirmed.

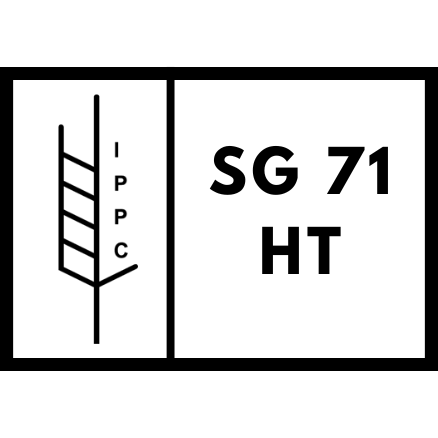

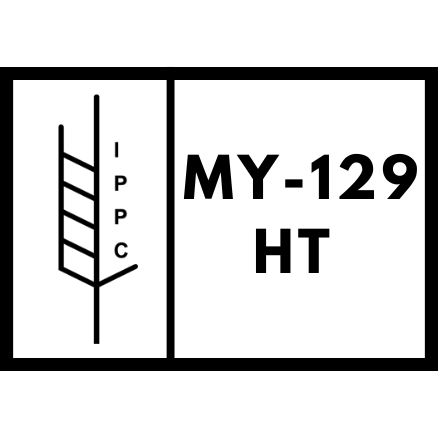

- Stamping & Marking: Once the treatment is completed and verified, each piece is stamped with the ISPM-15 mark, typically containing the IPPC symbol and a 2-letter country code, followed by a unique treatment facility code and HT (Heat Treatment) code.

- Post-treatment Handling: Treated wood is carefully handled to maintain its ISPM-15 compliance, as any significant alterations may require re-treatment.

- Preparation & Sorting: Similar to heat treatment, only solid wood packaging materials need to undergo fumigation. The wood is placed in a sealed area or fumigation chamber to prevent gas leakage.

- Introduction of Fumigant: The fumigant, typically methyl bromide, is introduced into the chamber at a specific concentration, depending on wood volume and temperature. This chemical penetrates the wood and effectively kills pests within a set timeframe.

- Dosing & Exposure: The wood is exposed to the fumigant for several hours (usually between 16-24 hours). The concentration of methyl bromide and exposure time will vary based on the wood type, temperature, and size of the load.

- Ventilation & Aeration: Once the exposure time is complete, the chamber is opened and thoroughly ventilated. This step allows residual gas to dissipate, ensuring the treated wood is safe for handling and shipment.

- Stamping & Marking: After treatment and aeration, each wood component is stamped with an ISPM-15 mark which includes the IPPC symbol and a two-letter country code, followed by a unique treatment facility code and an MB (Methyl Bromide) code.

- Post-fumigation Handling: The treated wood is kept in a clean environment to prevent contamination or pest re-infestation before shipping.

ISPM 15 is an international standard designed to prevent the spread of pests through solid-wood packaging. Compliant heat treatment or fumigation enables smoother customs clearance for export shipments.

It applies to solid-wood pallets, crates, and dunnage. Engineered wood products such as plywood, particleboard, Oriented Strand Board (OSB), and Laminated Veneer Lumber (LVL) are generally exempt.

Requirements can vary by consignee and route. We’ll advise what is typically accepted for your destination, and we recommend confirming with your forwarder or customer.

Heat treatment is generally the more economical and commonly accepted option. Fumigation is used when specifically required.

Some countries may require fumigation as a specific method of treatment, and fumigation is sometimes preferred when handling larger quantities of wood, or in cases where heat treatment may not be feasible.

Heat treatment certificates do not carry an expiry. Fumigation certificates are typically valid for 15 days from the fumigation date; please plan shipment accordingly.

In some cases, both treatments may be applied to wooden packaging. This happens typically if there are stringent requirements from specific countries.

In general, either heat treatment or fumigation will suffice for ISPM-15 compliance.

They are compliant post-treatment, but should be stored under shelter and kept away from potentially infested materials to prevent re-infestation before shipping.

Heat-treated pallets or boxed should be stored at least 5 meters away from infected items to prevent the spread of pests.

Compliant items carry the ISPM-15 stamp with the relevant HT code applied after treatment. We also maintain batch records for traceability.

No, provided the item remains intact and unmodified. Significant repairs or alterations may require re-treatment and re-stamping.

Non-compliant packaging risks delays, treatment at port, or disposal. We recommend confirming compliance before dispatch to avoid disruption.

We treat a wide range of wooden packaging! You may deliver items to our facility, or we can arrange collection and return on a scheduled basis. Our own transportation fleet enables us to collect and deliver your items efficiently and well.

Contact Us Today

Open a quote with our sales team today!

Our opening hours are Mon – Sat, 8:00 AM – 5:00 PM (SGT/MYT).

Malaysia Branch:

711, BT 4, Jalan Tampoi,

81200 Johor Bahru, Johor, Malaysia

(60) 07-332 8218

(60) 07-3326625