ISO Systems, ISPM-15, PEFC and Full Traceability

Our quality framework combines ISO-based procedures with ISPM-15 heat treatment (56 °C for 30 minutes), PEFC chain-of-custody and end-to-end traceability. Each batch is documented for audits and export checks, reducing shipment delays. We pair process control with training, safety and environmental programs to keep your operations compliant and on schedule.

Jump to the relevant section with the links below:

ISO 9001:2015 Certified | Traceable | Consistent | Customer-Focused

Our ISO 9001:2015 system governs every step—from incoming timber to finished goods—so your pallets, crates and packing solutions are built to the same specification every time. We maintain controlled documents, calibrated equipment, first-article checks and corrective/preventive actions, with full batch records available for audits and vendor

Traceability & Documentation

Each production lot is traceable to materials, processes and inspections. Your team receives a concise QA pack: batch IDs, spec conformance checklist, non-conformance resolution (if any) and shipping verification. On request, we map our checkpoints to your internal SOPs to simplify goods-in QA.

Meeting Global Standards for Seamless Trade

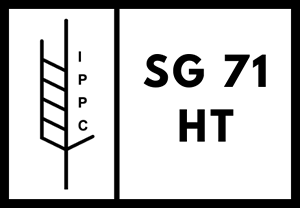

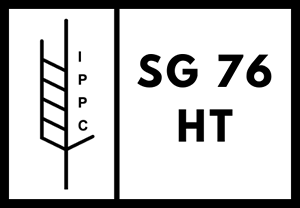

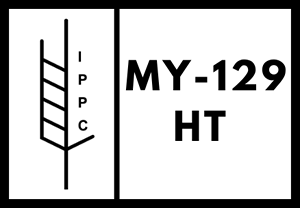

For export-bound shipments, pallets and crates are routed through ISPM-15 heat treatment with segregated flows and batch-level certificates. We log probe temperatures/time, label compliant lots, and attach digital certificates for customs. Domestic cycles bypass treatment unless you specify otherwise.

- Treatment spec: Heat treat to 56 °C for 30 min (wood core); probe-logged and saved against your batch ID.

- Marking: IPPC/ISPM-15 stamp on two sides (Country–Facility–HT = Heat Treated). Repaired pallets are re-treated and re-marked.

- Segregation: Export-ready lots held in clearly marked areas to avoid mixing with domestic pallets.

- Documentation: Treatment Certificate (PDF) + traceability sheet (SKUs, quantities, work performed). Probe summaries available on request.

- At goods-in/customs: Match batch ID ↔ certificate, verify stamps, proceed.

- Special cases we handle: Composite panels (exempt under ISPM-15), moisture dry-down, customer policies (HT-only).

Circular & Green Initiatives

We treat sustainability as operational discipline: design for reuse, verify sources, and measure what matters so customers get reliable, compliant packaging with a lower footprint.

Since 2021, Yat Guan been offering PEFC-certified timber options for new builds and replacements and maintain chain-of-custody separation where specified. In parallel, our Pallet Repair & Reconditioning program extends the service life of your pallets through structured inspection, grading, repair, and optional ISPM-15 for export. Complementing both, we continue to tighten our efficiency and reduce our carbon footprint throughout our production and logistical pipelines.

Chain-of-Custody You Can Trust

Choose PEFC-certified timber to align with ESG and tender requirements. We maintain chain-of-custody (CoC) controls from intake to delivery—segregating certified stock, recording volumes, and issuing documents that make audits simple.

- Certification scope: PEFC Chain-of-Custody in place; certificate number shown on request and on relevant documents.

- Stock control: Certified material is segregated (or quantity-controlled) to protect claim integrity across production.

- Claims on paperwork: Delivery notes/invoices can include PEFC claim and, where needed, the CoC certificate number for your audit trail.

- Documentation pack: Species/origin (where available), product spec, quantities, and PEFC status summarized for procurement.

- Mixed orders: We can fulfil certified and non-certified lines in the same PO—clearly identified so your team can book them correctly.

- Logo & label use: We follow PEFC’s trademark rules; if you need product or packaging labels, we’ll verify artwork before use.

- Edge cases handled: Mixed-species items, recycled content, substitutions, or urgent swaps are documented so your PEFC records remain clean.

Sustainability Commitment

We offer PEFC chain-of-custody timber on request, with claim and certificate details provided on delivery paperwork—simple for audits, seamless for operations.

Extend Lifespan, Reduce Waste, Protect Uptime

Our pallet repair and reconditioning program keeps wooden pallets in circulation longer, lowering total cost of ownership and landfill waste while maintaining safe, reliable handling. Each pallet is inspected, graded, repaired, and—where export is required—optionally ISPM-15 heat-treated. Units are marked and cycle-tracked for traceability and QA audits, with batch summaries available for your records.

- Service scope: structural repairs, board/block replacement, nail reset, deck alignment, optional ISPM-15 retreatment for export lots.

- Quality assurance: standardised inspection grades, usability warranty on repaired units, batch-level reports and certificates where applicable.

- Operational benefits: fewer urgent purchases, lower breakage and downtime, stable dispatch schedules, consistent load performance across your network.

- Measured outcomes: longer pallet lifecycle (tracked repair cycles), CO₂ and waste reduction per batch, and cost savings versus buying new.

- Compliance options: where new materials are needed, PEFC-certified timber can be specified on request to support responsible sourcing.

Need a closed-loop option right now?

See how we inspect, grade, repair, and track units end-to-end on our Pallet Repair Service page. Includes turnaround windows, usability warranty, ISPM-15 (on request), and batch-level traceability.

Leaner operations, lower emissions, measurable savings

We design for throughput and impact. Route-optimised deliveries, energy-efficient heat treatment, and material recovery keep your schedule tight while lowering waste and emissions—without adding steps for your team.

Route Optimisation

Consolidated runs and smart backhauls reduce empty miles and curb fuel burn while protecting delivery windows

Energy-Efficient HT

Calibrated cycles and load planning cut chamber time per pallet—meeting ISPM-15 specs with less energy.

Material Recovery

Non-conforming pallets are dismantled for component reuse; unusable timber goes to recycling streams instead of landfill.

Sustainability Ledger

Monthly roll-ups of pallets recovered, waste diverted and estimated CO₂e saved—ready for ESG reporting.

Investing in Skills, Safety & Sustainable Growth

At Yat Guan, we believe that performance begins with people. Our commitment to safety, training, and fair growth ensures that every pallet and crate we deliver reflects the same care we extend to our workforce.

We are proud to be bizSAFE Level 4 certified, a recognition of our structured Workplace Safety and Health Management System (WSHMS) aligned with Singapore’s national standards.

This means risk management, hazard control, and safety awareness are built into every stage of our operations — from timber processing and assembly to warehouse handling and delivery. It’s how we protect our team and ensure reliability for our customers.

In parallel, our participation in Singapore’s Progressive Wage programme reinforces our belief that fair wages and continuous upskilling go hand in hand with productivity and quality.

Through structured wage progression and training pathways, our employees gain the skills and confidence to perform safely, innovate, and grow within the company.

What this means for our partners

- A well-trained, safety-conscious workforce handling your products and assets

- Reduced operational risk and consistent throughput across sites

- Higher quality standards, driven by motivated and accountable teams

- Ethical sourcing and labour practices that align with your ESG commitments

At every level, empowering our people means elevating your performance — safely, sustainably, and responsibly.