Description

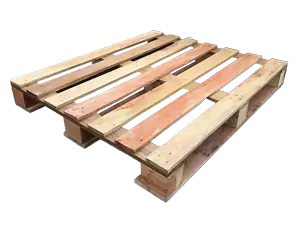

Engineered for machinery and oversized loads, our wooden skids deliver strong, low-profile support without a full bottom deck. We model runner layouts to your centre-of-gravity, lift points, and handling method (fork, jack, crane, or drag), then build in premium hardwood/softwood or engineered boards. Export-ready with ISPM-15 and PEFC-certified timber on request. Manufactured in Singapore and Malaysia.

Material options

- Kiln-dried hardwood/softwood; target moisture 16–22%

- Sustainable options: Acacia, or PEFC-certified timber available

- Engineered boards: LVL or plywood bearers/decks for added stiffness

- Anti-mould treatment; ring/screw-shank nails or bolts per duty class

Compliance options

- ISPM-15 heat treatment with IPPC stamp + digital HT certificates

- Batch-level probe logs and QA checks; PEFC chain-of-custody on request

- Optional load/deflection test reports for audits

Design options

- Footprint: 800 x 1200 mm up to 2400 x 4000 mm (custom)

- Runners: 2–6 pcs, 70–120 mm W x 90–140 mm H; spacing to COG/lift points

- Deck/bearers: 18–25 mm boards or LVL/ply caps; open or partial deck

- Clearance: 90–120 mm for pallet jacks/forks; chamfered lead edges

- Handling features: fork notches, perimeter cleats, banding grooves, bolt-through holes, tie-downs, anti-slip and moisture-resistant finishes

Key features

- Custom static/dynamic load ratings

- Runner layouts matched to lift/drag paths

- Repairable and recyclable (buy-back available)

- Fast lead times; export certificates provided

- Typical specs (indicative)

- Working load: up to 3–5 t dynamic; 8–10 t static (engineered to suit)