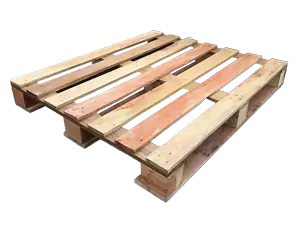

Description

High strength, consistent, export-ready

Our laminated veneer lumber pallets (LVL pallets) deliver higher stiffness, straighter members, and superior fastener holding versus plywood – ideal for rack, conveyor, and repeat-cycle use. Pure-LVL builds are typically ISPM 15 exempt; mixed builds can be supplied ISPM 15 heat-treated for export.

Why LVL over plywood

- Stronger runners/blocks: long-grain veneers aligned for higher bending strength and less splitting.

- Better fastener grip: excellent nail/screw withdrawal vs plywood edges.

- Dimensional stability: straighter members, tighter tolerances – great for ASRS, racking, and conveyors.

- Durability: resists edge bruising and delamination common in heavy traffic.

Materials options

- Structural LVL (e.g., Radiata/Poplar/Hevea/Styrax); moisture ~8–12%

- PEFC chain-of-custody LVL available

- LVL runners/blocks with optional LVL or plywood decks (closed or open)

Compliance options

- ISPM 15 exempt for all-LVL constructions (most lanes)

- ISPM 15 heat treatment for mixed LVL/solid-wood builds

- Export paperwork & batch/QR traceability on request

- Identification: optional paint banding and stencilled IDs for fleet control

Design options

- 2-way or 4-way pallet geometries

- Open or closed deck; perimeter base or 3/5-runner layouts

- Load tuning for parcel to heavy-duty applications; custom sizes (e.g., 1000 x 1200, 1100 x 1100, 40 x 48 in)